Caravan Sideboard

Palomar

Competence and Reliability

About Us

Located in Tuscany, the beating heart of the PleinAir industry, Palomar Srl is a leading company in the production of high-quality sandwich panels and semi-finished components for caravans and mobile homes. The company was founded in 2003 by the merger of three societies already present in the sector, headed by the Bagni, Giotti and Nencioni families and it’s now lead by a team of young entrepreneurs, skilled staff and avantgarde machinery to satisfy its customers with its premium services.

The Area

Palomar comprehends four production sites, in the industrial area of Bassetto in Certaldo, for a total of about 10,000 square meters.

Products

Sawmill

The first step of the production process, foresees the cutting of the planks through CNC machines with length optimizer and relative selection of defects to guarantee the quality of the product. In the assembly phase, in fact, only those selected materials are used.Assembly

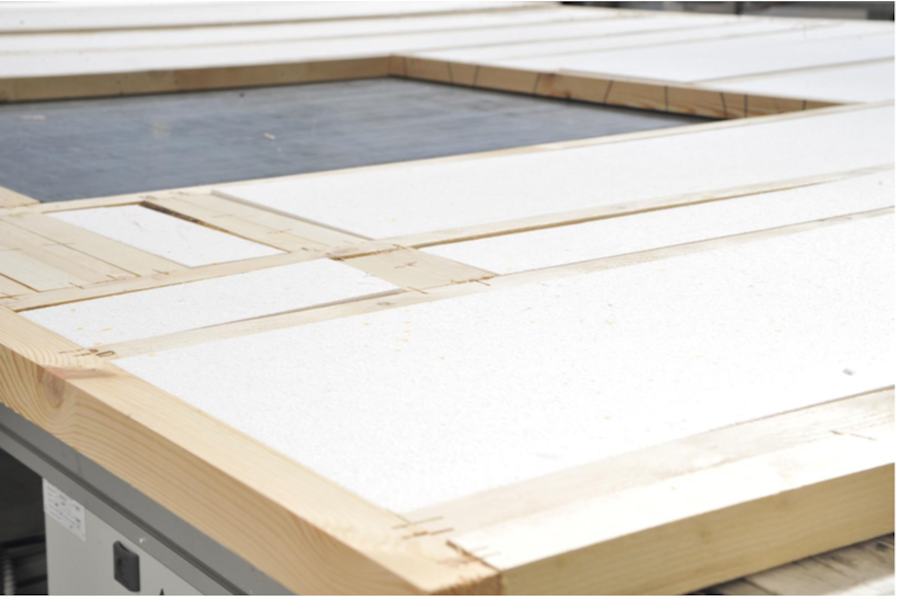

According to the established draft, given by the client, the technicians are able to design the realization of wooden and PVC frames following the costumer’s need: any type of panel has its own soul, its skeleton and on this we strive to give the right consistency and strength to finished product.Poystyrene Cut

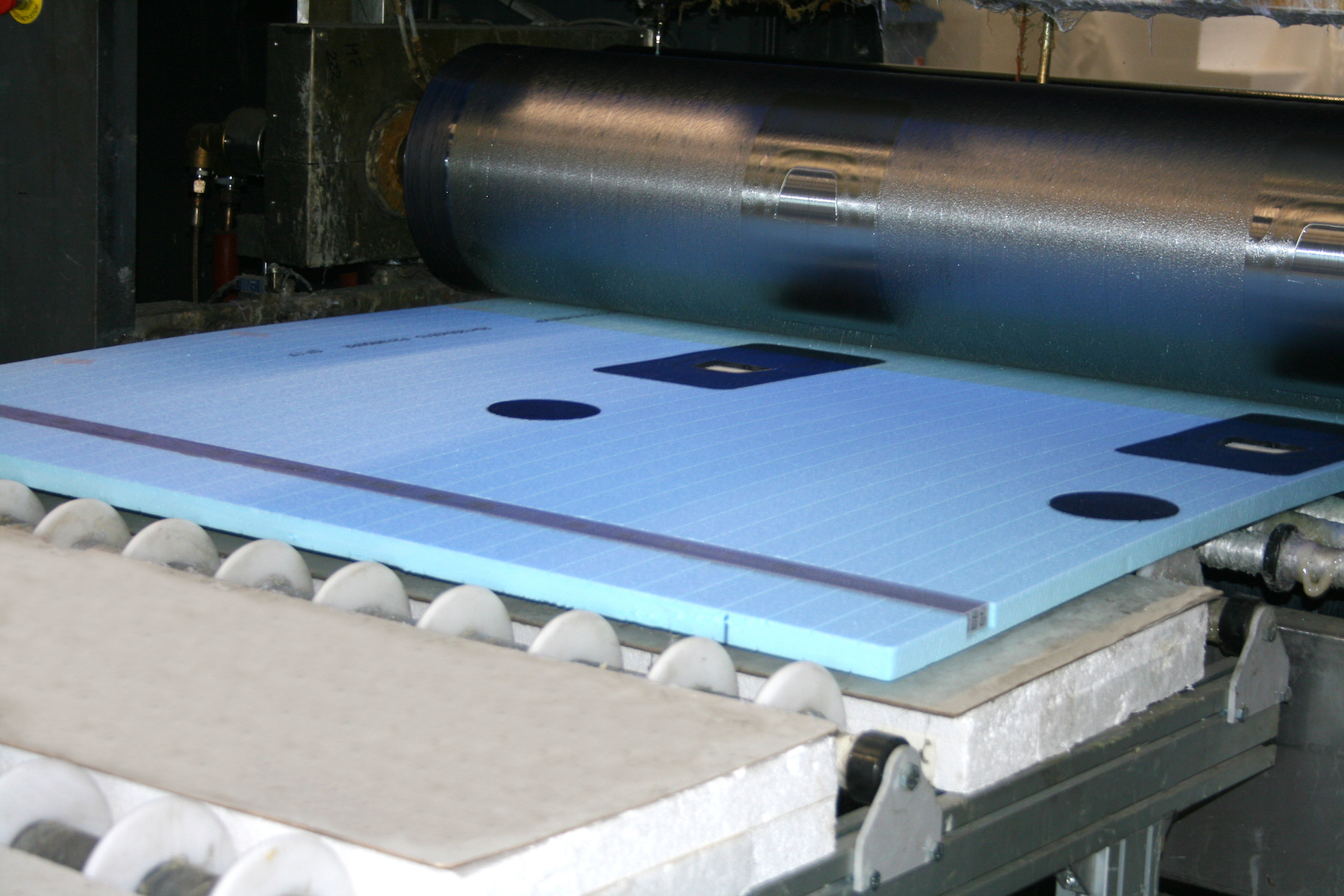

One of the quality materials that are used for the construction of panels, both for campers and mobile homes, is polystyrene: highly ductile material that however needs the right support. As with cutting, thanks to new generation machines, we are able to make highly precise sections, so as to perfectly follow the project guidelines.Panels Cut

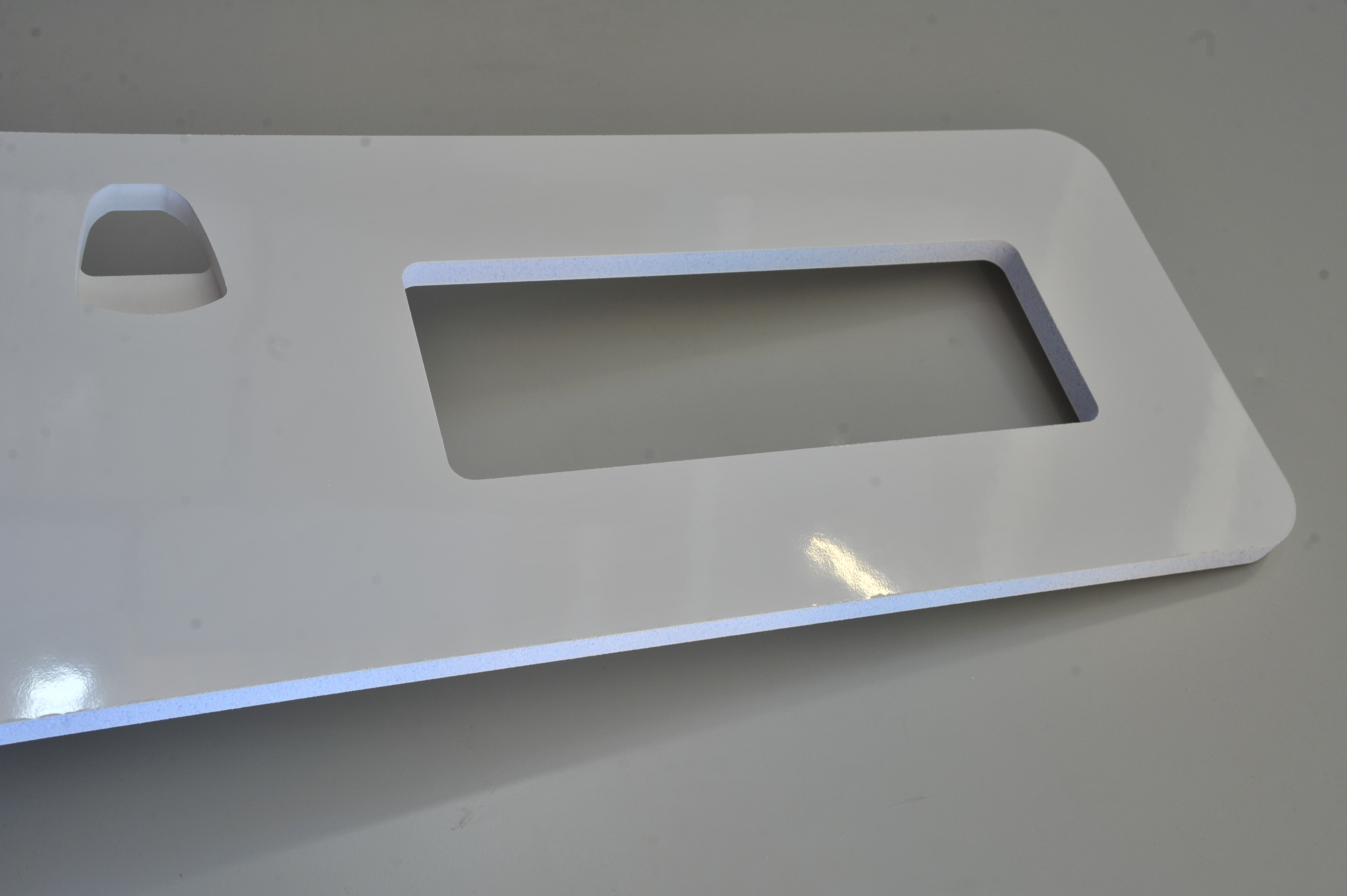

Even once assembled and ready to be finished, a panel may need a further cutting or shaping: this is possible thanks to CNC sizing machines able to offer a very high percentage of precision and reliability.Pantograph

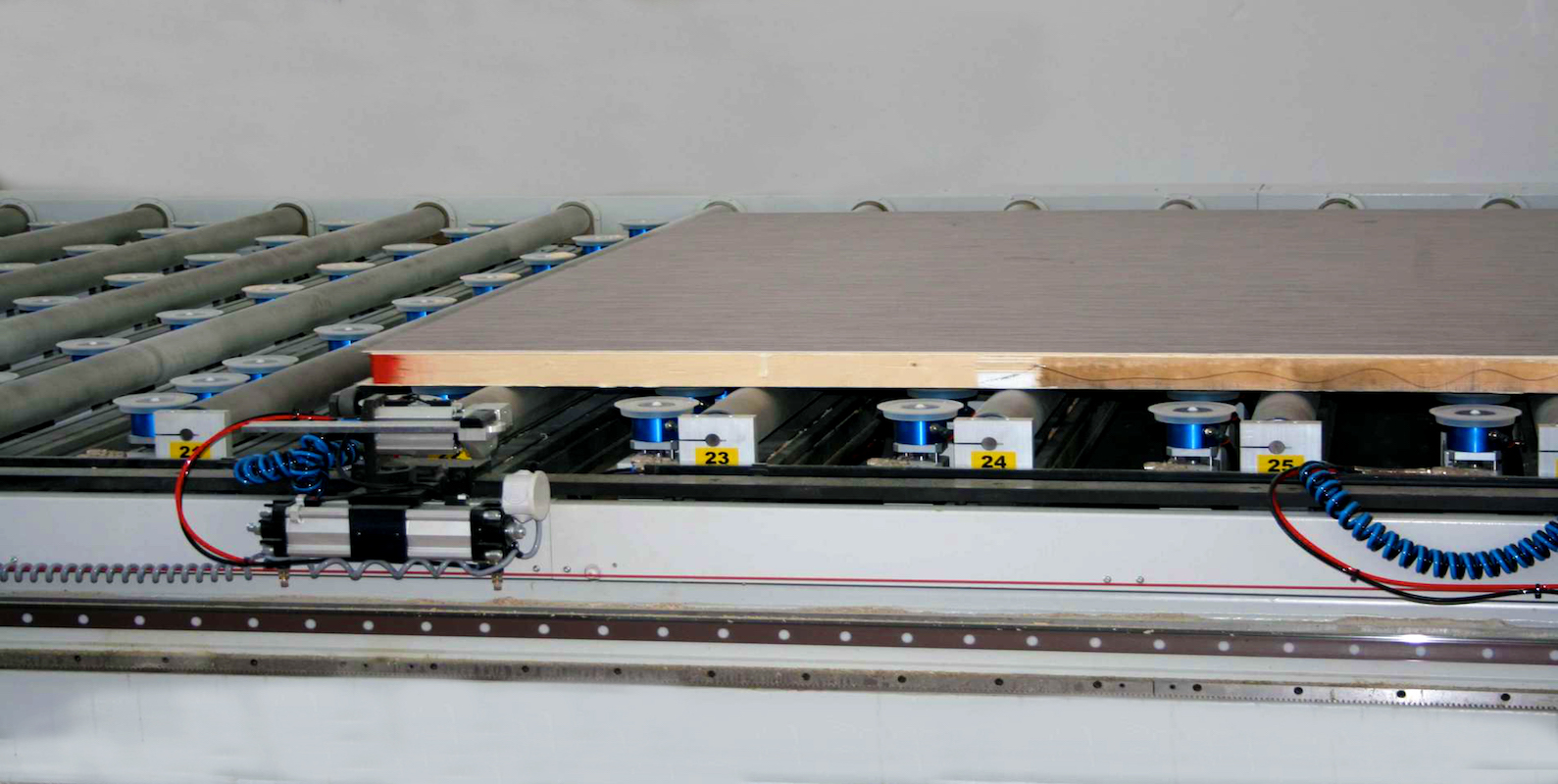

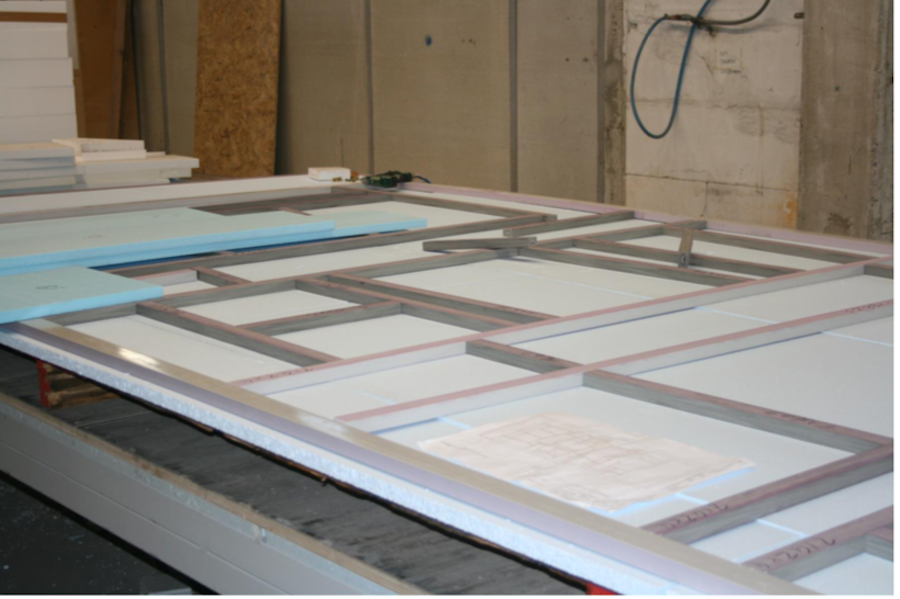

The company has seven working centers with different sizes to make any type of panel. In this case too, the latest generation of machines follow what is commissioned to them during the design phase, but the precision and reliability of the pantographs themselves makes it possible to create not only high quality panels, but also structures capable of being assembled in a perfect way to the various situations that are required by customers and not just campers and mobile homes.Boning

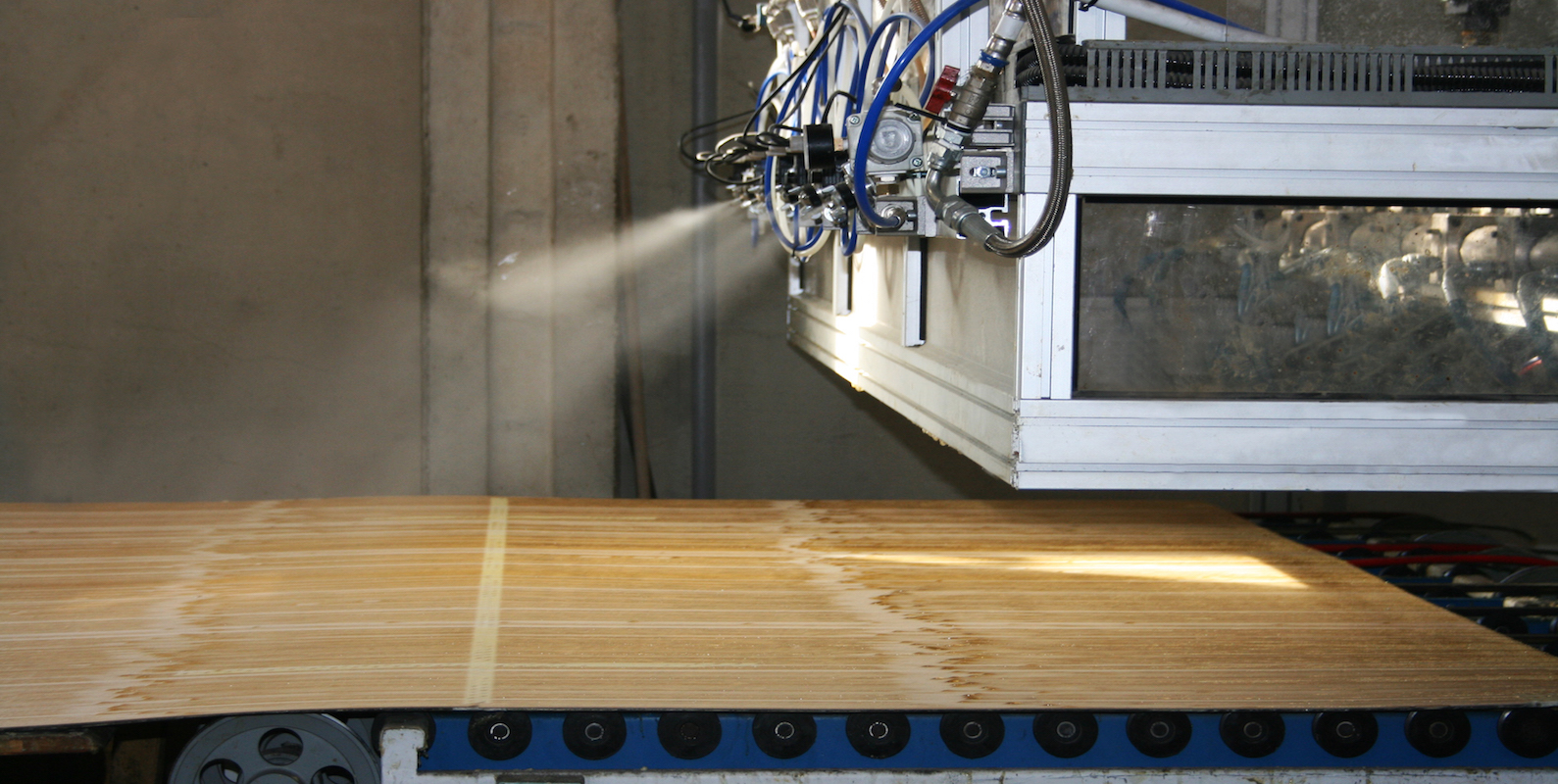

The company has six different gluing lines with polyurethane adhesive distributed flush, while great performance can be offered by the gluing line with polyurethane adhesive distributed with spray guns. For greater consistency and strength, 100% reactive hot melt adhesive lines are used, distributed by roller spreading machine and glue-based glue-based glueing.Gallery

-

Sawmill

Cutting of the plank -

Sawmill

Cutting of the plank -

Sawmill

Cutting of the plank -

Assembly

Construction of structures -

Assembly

Construction of structures -

Assembly

Construction of structures -

Polystyrene Cut

Quality - Accuracy -

Polystyrene Cut

Quality - Accuracy -

Polystyrene Cut

Quality - Accuracy -

Panels Cut

Cutting or shaping -

Panels Cut

Cutting or shaping -

Panels Cut

Cutting or shaping -

Pantographs

WebdesPantografi CNC -

Pantographs

WebdesPantografi CNC -

Pantographs

WebdesPantografi CNC -

Bonding

4 gluing lines -

Bonding

4 gluing lines -

Bonding

4 gluing lines

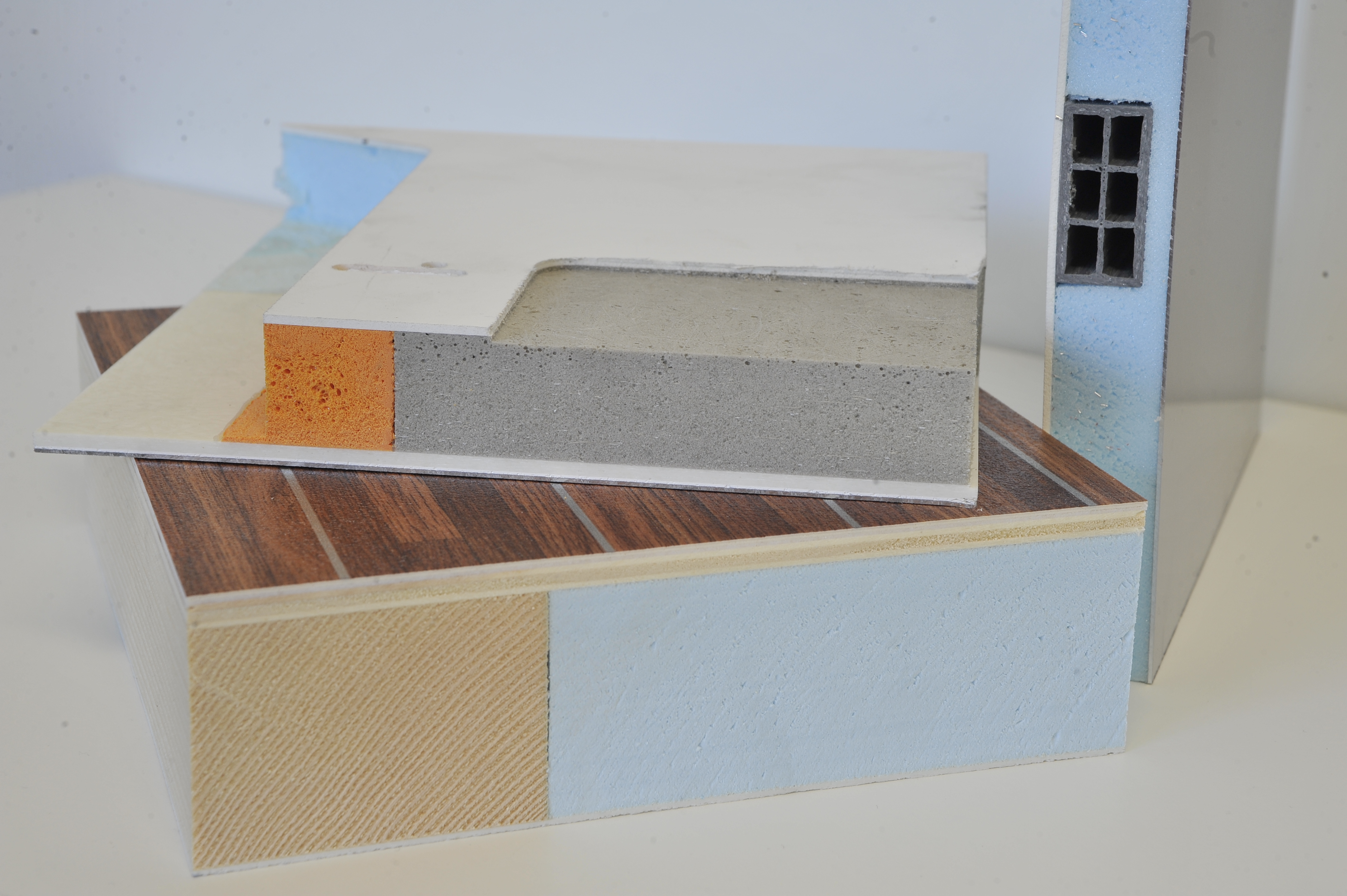

Products

Palomar core business is not only wood manufacturing and assembly of panels according to the needs and characteristics required by the customers but even more. Thanks to seven working centers equipped with CNC technology of different sizes and six bonding lines of liquid polyurethane, spray, hot melt and vinyl glue, the company is able to produce walls, roofs and floors for caravans and mobile homes and smaller elements such as doors, windows and different semi-finished products, even edged. Depending on the production season, employees range from 50 to 90 people to maintain a flexible structure. The continuous search for new materials and increasingly refined production methods means that the range of action of Palomar extends beyond the world of PleinAir, embracing the furniture, van and building sectors.

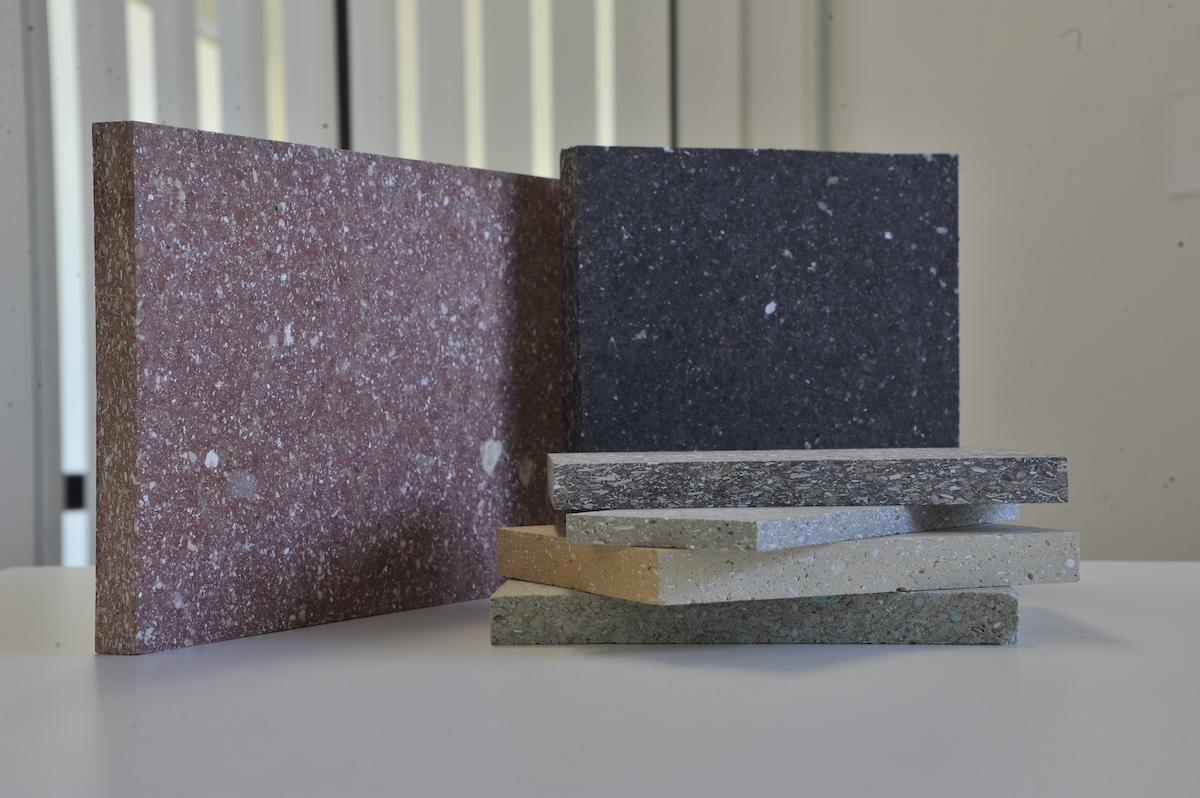

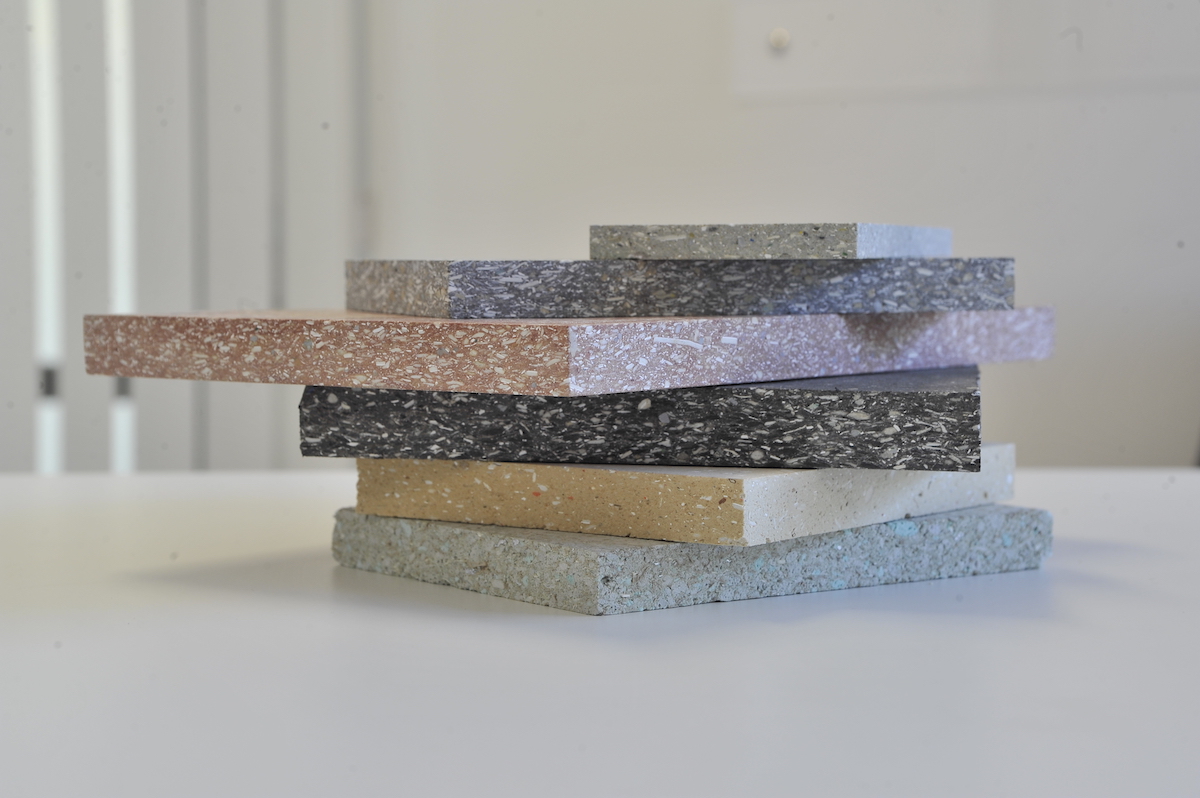

Palomar Green

ISO 9001 certified , Palomar pays special attention to the reuse of processing waste that makes the

company eco-sustainable and oriented towards renewable energy. The R & D division has selected a new

product to be placed on the market, it is a material obtained from fiberglass recycling, fireproof, waterrepellent

and without any disposal issue because it is recyclable again. It is meant to be an alternative to

wood and it is suitable for the realization of shower trays, kitchen tops and furniture in general.

Partners

Always engaged in the production of sandwich panels, Palomar works for several national and international groups in the sector